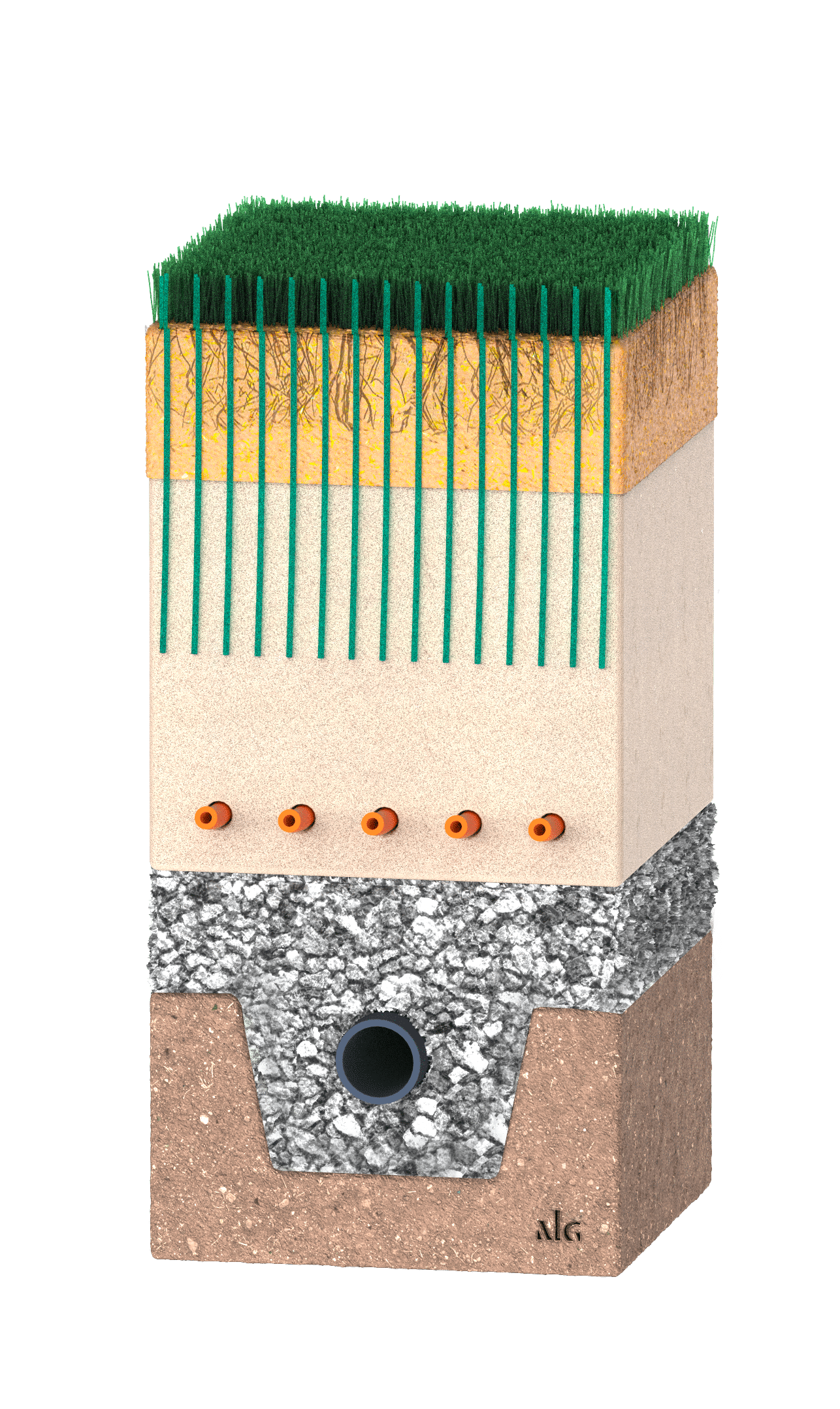

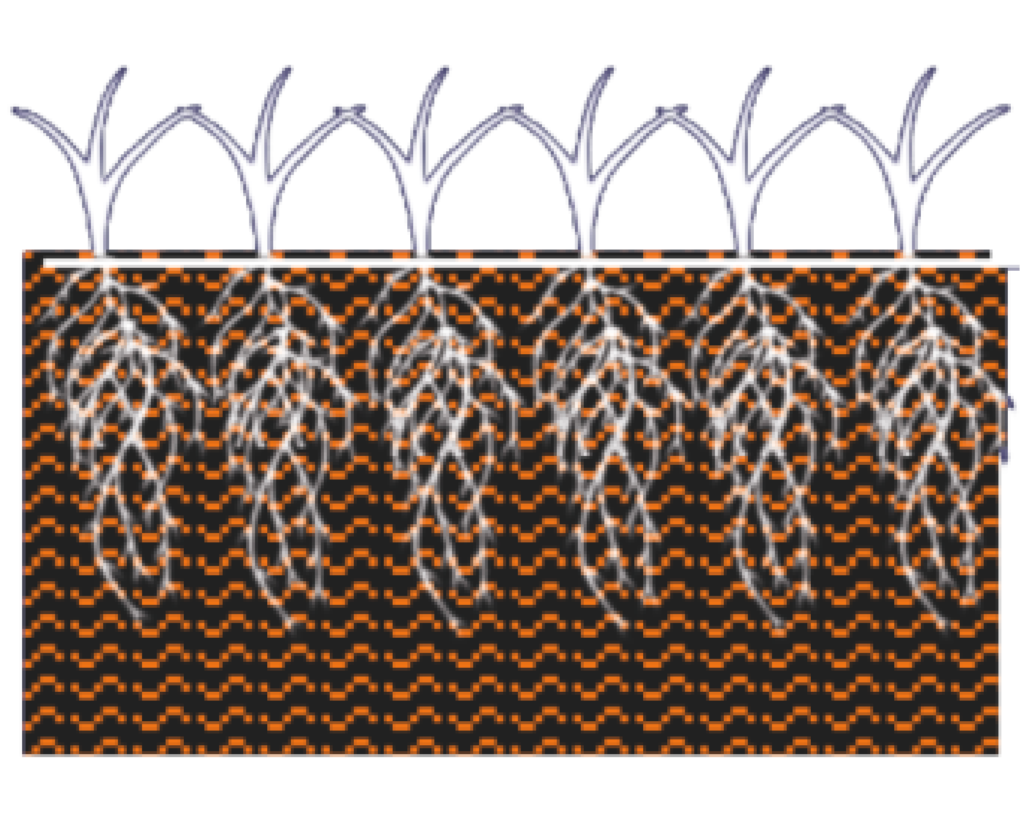

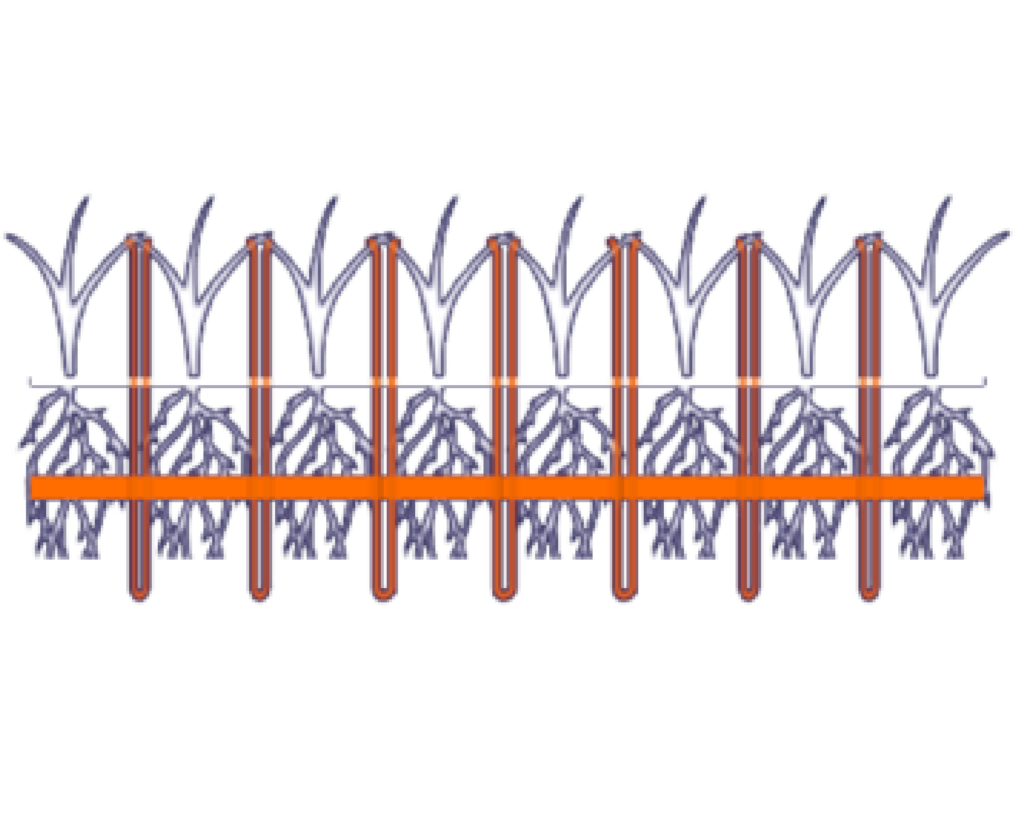

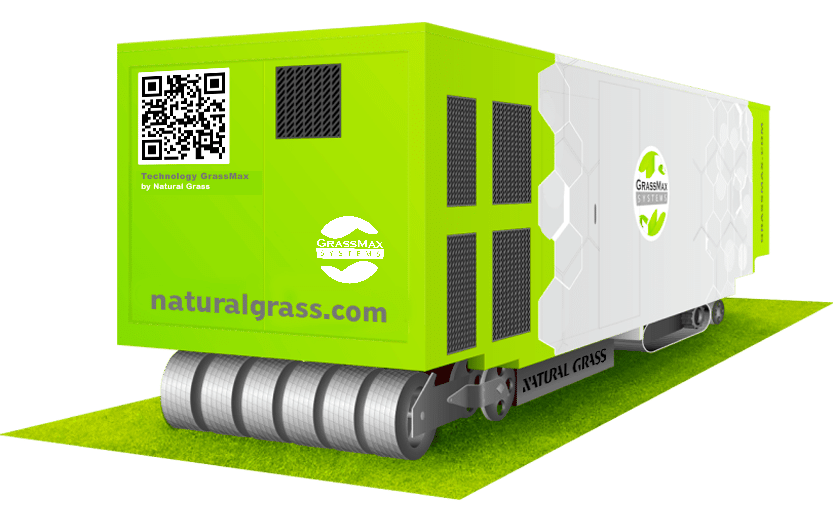

State-of-the-art stitching

The hybrid grass system called “stitching” consists of injecting synthetic fibers on the ground, every 2 centimeters, to a depth of 18 centimeters. This system increases the horizontal and vertical stability of the natural surface.